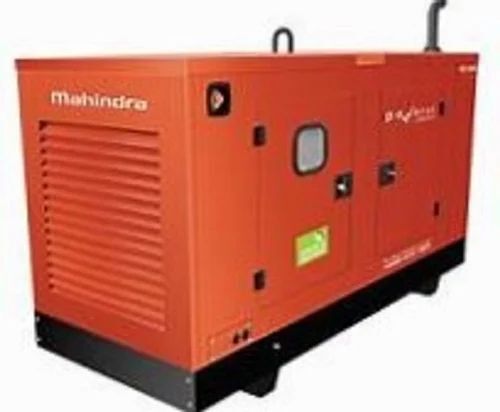

Portable Diesel Generator Supplier in Vadodara

Price 180000 INR/ Unit

MOQ : 1 Unit

Portable Diesel Generator Supplier in Vadodara Specification

- Warranty

- 1 year

- Usage & Applications

- Industrial

- Rated Voltage

- 110-215 Volt (V)

- Phase

- 3

- Material

- MS

- Features

- Good Quality

- Frequency

- 50-60 Hertz (HZ)

About Portable Diesel Generator Supplier in Vadodara

FAQs of Portable Diesel Generator Supplier in Vadodara:

Q: What is the frequency range of the Portable Diesel Generator?

A: The frequency range of the Portable Diesel Generator is 50-60 Hertz (HZ).Q: Is the generator suitable for outdoor usage?

A: Yes, the generator is outdoor-rated with an IP65 rating.Q: What is the rated voltage of this generator?

A: The rated voltage of the generator is 110-215 Volt (V).Q: What type of material is used in the construction of this generator?

A: The generator is made of MS (Mild Steel).Q: What is the warranty duration for this generator?

A: The generator comes with a warranty of 1 year.Q: Is the generator designed for industrial applications?

A: Yes, the Portable Diesel Generator is specifically designed for industrial usage and applications.Q: What phase does the generator operate on?

A: The generator operates on 3-phase power.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Diesel Generator Category

82.5 to 200 kVA Diesel Generator

Price 1000000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : Yes

Product Type : Diesel Generator

Diesel Generator Set 5 to 320 KVA Mahindra Power

Price 2500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Features : Good Quality

Material : MS

Mahindra Diesel Generator

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Features : Good Quality

Product Type : Mahindra Diesel Generator

Material : MS

Send Inquiry

Send Inquiry